A jewel-like façade encircles Koffi and Diabaté Architects’ new project in Abidjan, the economic capital of Ivory Coast.

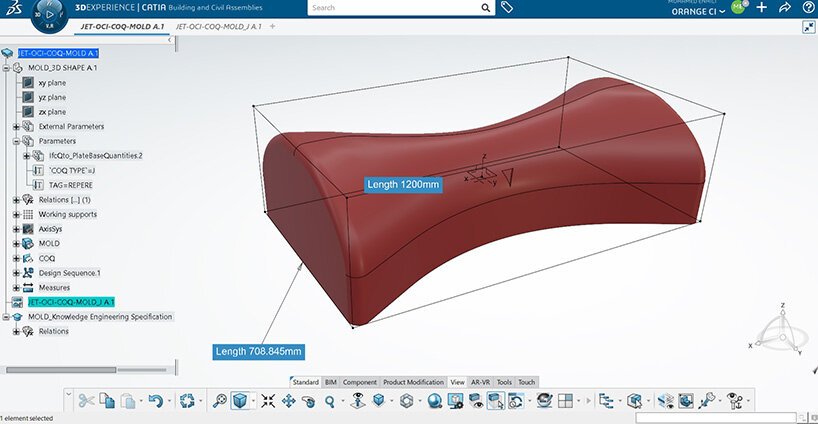

The orange côte d’ivoire headquarters, part of the French multinational telecommunications corporation, will rise up seven stories, totalling over 15,000 sqm of floor space. A 4,000 sqm intricate, art-like frame wraps around the exterior comprising 4,000 unique double curved parts. This personalized sophisticated surface weave was digitally developed in collaboration between Jet Contractors and Dassault Systemes, industry leader in 3D design and engineering software.

Jet contractors is a fully integrated group that operates in Morocco and elsewhere on the African continent, combining 30 years of leading expertise in engineering, procurement, manufacturing and construction. Recent projects include the kenitra high-speed train station by omar kobbité architectes and silvio d’ascia architecture, and the soon-to-be-completed grand theatre of rabat by zaha hadid architects.

How Jet Contractors and Dassault Systemes Collaborated to Execute the Facade Design

The jewel-like façade references the site location, which is sandwiched between a lush oasis of water and a golf course. The form and indentations of the sport balls have been translated into the design. The continuous curve of the building made the elements of the façade even more complex to create.

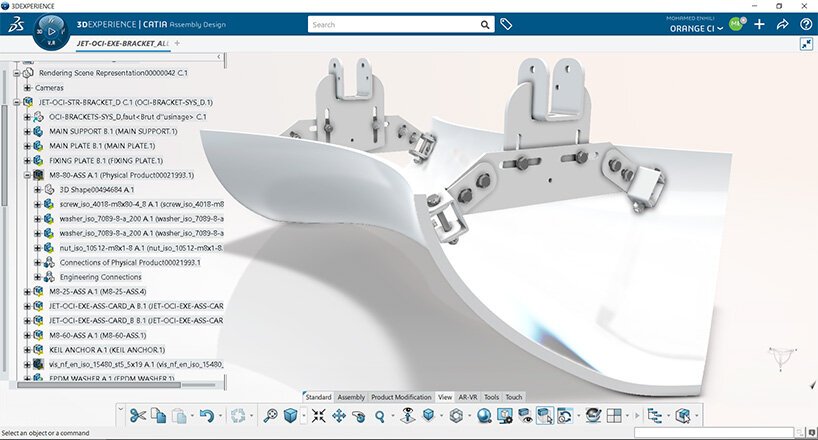

The complexities of the curving, golf ball-inspired façade was a challenge Jet Contractors team. It called for a closer relationship with technological experts – and their tools – in digital transformation in the architecture, engineering and construction industry. In came Dassault Systemes, who elevated jet contractors’ toolset to transition to the more personalized nature of their 3DEXPERIENCE platform.

About the 3DEXPERIENCE platform.

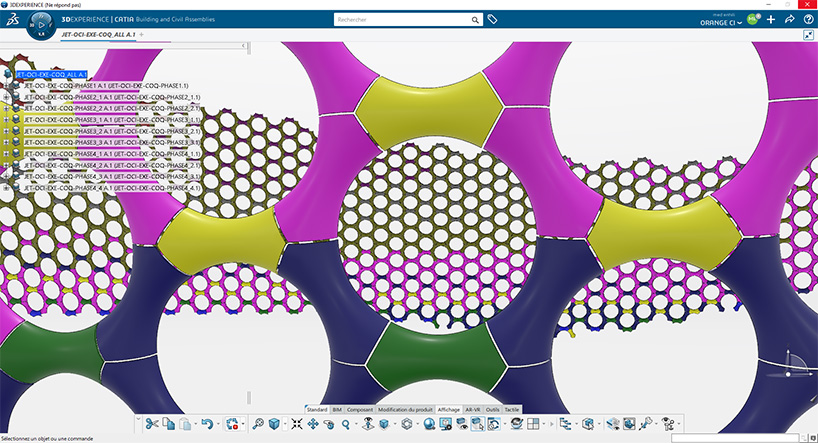

The 3DEXPEREINCE platform enabled jet contractors to design the façade. This started with the geometry, as each of the 4,000 parts needed to be unique to encase the double curved architecture but unite to a uniform pattern. CATIA and its xGenerative design tools formalized the computation design, meaning bespoke elements could be created using shared reference geometries and parameters to generate a whole assembly. This aided the design for manufacturing & assembly, reducing the risks whilst increasing both the productivity and quality. The developers could understand how their design decisions performed in virtual twin experiences, enabling a history of modifications, automation processes up to production, and lifecycle management.

The 3DEXPERIENCE platform operates on the cloud, meaning collaborators can join from any location and any device with internet. This is especially ideal with projects underway during times when travel is difficult. The online platform also enriches the support available. The community engages other professionals within the architecture, engineering and construction industry and further afield to share knowledge. Dassault systemes’ team of architects and engineers are also on hand to assist. They collaborate to tailor tools to find the perfect solution for each project.